Why Regular Maintenance Is Crucial for Fire Pumps: Protecting Lives and Property

In the world of fire safety, fire pumps are the unsung heroes. These systems play a critical role in ensuring that water is delivered with the necessary pressure to suppress fires, protect lives, and prevent property damage. However, to function effectively in an emergency, fire pumps require regular maintenance. For building owners, facility managers, and safety professionals, understanding the importance of this maintenance is key to upholding fire safety standards and compliance.

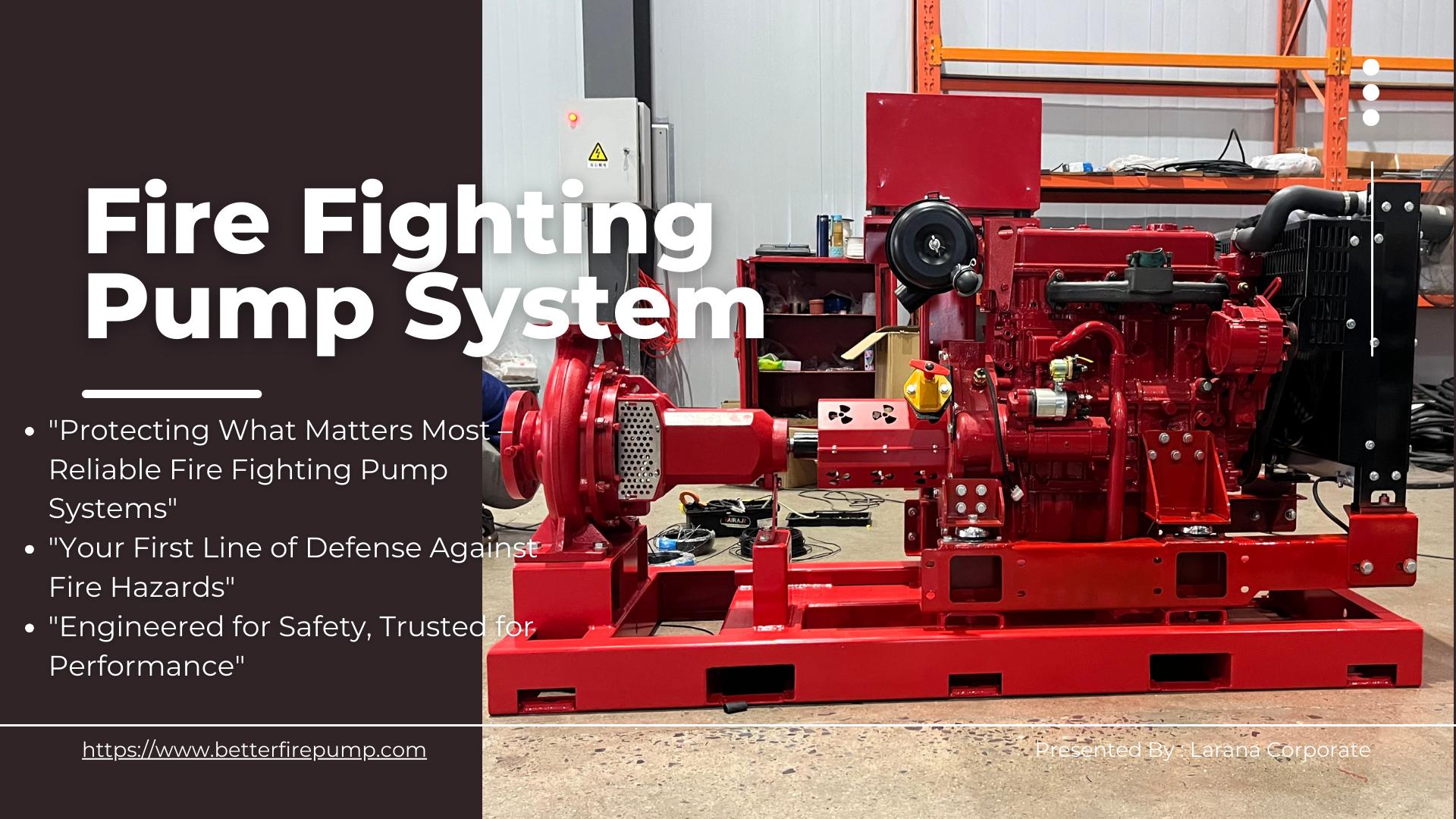

At Better Pump, we’ve spent over a decade supplying and supporting fire pump systems, and we’ve seen firsthand the difference that consistent maintenance can make. Let’s explore why regular fire pump maintenance is crucial and what practices should be implemented to keep these vital systems in peak condition.

1. Ensuring Readiness in Emergencies

Fire pumps often sit idle for extended periods, waiting for an emergency to occur. While they are designed to remain reliable and ready, without regular checks, the probability of failure increases. Dust, moisture, and corrosion can build up over time, leading to mechanical issues that may prevent the pump from starting when needed. Regular inspections and maintenance ensure that pumps are fully functional and ready to perform at a moment’s notice.

2. Compliance with Standards and Regulations

In many regions, fire pump maintenance isn’t just a recommendation; it’s a requirement. For instance, compliance with NFPA 20 standards and UL listings—key certifications that we uphold at Better Pump—requires adherence to strict testing and maintenance routines. Regulatory bodies conduct inspections to verify compliance, and failure to maintain fire pumps could result in fines or operational shutdowns. Staying compliant with these standards through regular maintenance not only keeps you within the law but also assures occupants that you’re committed to their safety.

3. Extending the Life of Equipment

Fire pumps represent a significant investment, and like all mechanical equipment, they experience wear and tear. Maintenance helps to identify potential issues before they become costly problems, extending the life of the pump and related equipment. Routine tasks, such as lubrication, part replacements, and clearing obstructions, ensure that the pump runs smoothly and remains operational for years. This preventive care minimizes downtime and reduces the need for costly repairs or replacements.

4. Reducing False Alarms and Unnecessary Disruptions

Improperly maintained fire pumps are prone to malfunctions, which can lead to false alarms. These alarms not only disrupt daily operations but also cause unnecessary stress for building occupants and responders. Routine maintenance helps to ensure the system only activates when needed, improving reliability and avoiding interruptions in day-to-day activities.

5. Protecting Lives and Assets

Ultimately, the purpose of a fire pump is to protect lives and property. A well-maintained fire pump provides peace of mind, knowing that if a fire breaks out, the system will perform as expected. This assurance is invaluable to building owners, facility managers, and occupants, as it reinforces a commitment to safety and reduces the risk of extensive property damage or even loss of life.

Key Maintenance Practices for Fire Pumps

Now that we understand why maintenance is crucial, let’s look at some recommended practices:

-

Weekly and Monthly Tests: Conducting regular “churn” tests (also known as no-flow tests) helps to verify that the pump starts and runs without water being discharged.

-

Annual Inspections: Each year, conduct a comprehensive inspection to check the pump, motor, control systems, valves, and all electrical connections. This inspection should be performed by certified technicians, ensuring compliance with NFPA 20 and UL requirements.

-

Battery and Diesel Engine Checks: For diesel engine pumps, regularly check the batteries and fuel systems to ensure they are fully operational. Similarly, test electric pumps for power supply consistency.

-

Monitoring Temperature and Vibration: Abnormal temperature or vibration could indicate issues with the bearings or other mechanical parts. Regular checks can catch these signs early, avoiding major breakdowns.

A Reliable Fire Safety Partner

At Better Pump, we understand the critical role that fire pumps play in fire safety, which is why we’re committed to not only manufacturing high-quality fire pump systems but also educating our customers on the importance of maintenance. By working together to prioritize fire pump maintenance, we can ensure these systems are ready when they’re needed most.

If you have questions about maintaining your fire pump systems, or if you’re looking for a trusted partner in fire safety, feel free to reach out. Let’s keep safety at the forefront, one pump at a time.