What to Consider When Using Diesel Engine Fire Pumps

Jun 02, 2023

Share:

Introduction:

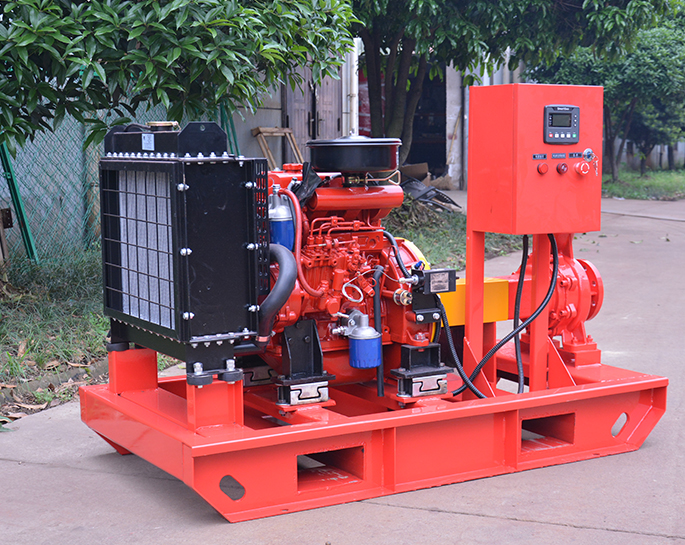

Diesel engine fire pumps play a crucial role in ensuring the safety of lives and property during emergencies. These powerful devices provide a reliable source of water for fire suppression systems, making them an essential component of fire protection infrastructure. However, it is vital to pay close attention to certain factors when using diesel engine fire pumps to ensure their efficient and safe operation. This essay explores key considerations that should be kept in mind to maximize the effectiveness and reliability of diesel engine fire pumps.

Regular Maintenance:

One of the primary aspects to focus on when using diesel engine fire pumps is regular maintenance. Routine inspections, servicing, and preventive maintenance are essential to keep the pumps in optimal condition. It is crucial to follow the manufacturer's recommendations regarding maintenance schedules, oil changes, fuel filter replacements, and overall system checks. Neglecting maintenance can result in decreased performance, increased fuel consumption, and even pump failure during critical situations.

Fuel Quality and Storage:

Diesel engine fire pumps rely on high-quality fuel to function efficiently. It is crucial to use clean, contaminant-free diesel fuel to avoid clogging the system or causing engine malfunctions. Regularly inspect and clean the fuel tank, and ensure proper filtration to prevent impurities from entering the engine. Additionally, attention should be given to the storage conditions of the fuel, including temperature control and protection from water or moisture intrusion.

Proper Ventilation:

Proper ventilation is essential for diesel engine fire pumps to operate effectively. These engines produce exhaust gases that contain harmful substances, such as carbon monoxide. Adequate ventilation helps dissipate these gases and prevents the buildup of toxic fumes in the pump room. Ensure that the pump room has sufficient air exchange, proper exhaust systems, and adheres to local regulations for ventilation standards to safeguard the health and safety of personnel.

Regular Testing and Training:

Regular testing and training are crucial for diesel engine fire pumps. Conducting periodic performance tests ensures that the pumps are functioning within acceptable parameters. This includes testing the pump's flow rate, pressure, and suction capabilities. Moreover, training personnel on the correct operation and maintenance procedures is vital to ensure their competence and familiarity with emergency protocols. This proactive approach enhances the response time and effectiveness of the fire suppression system when the need arises.

Backup Systems and Redundancy:

To ensure uninterrupted fire protection, it is important to have backup systems and redundancy in place. Diesel engine fire pumps should be equipped with backup power sources, such as generators or battery systems, to mitigate the risk of power failures during emergencies. Additionally, having redundant fire pumps installed can serve as a fail-safe mechanism, providing backup in case of pump failure or maintenance requirements. Regularly test and maintain these backup systems to ensure their reliability when needed.

Conclusion:

Diesel engine fire pumps are crucial for effective fire suppression systems, and paying attention to specific factors can significantly enhance their reliability and performance. Regular maintenance, fuel quality and storage, proper ventilation, regular testing and training, and the presence of backup systems are key considerations to prioritize. By adhering to these guidelines, fire protection systems can be confidently relied upon during critical situations, protecting lives and property effectively.

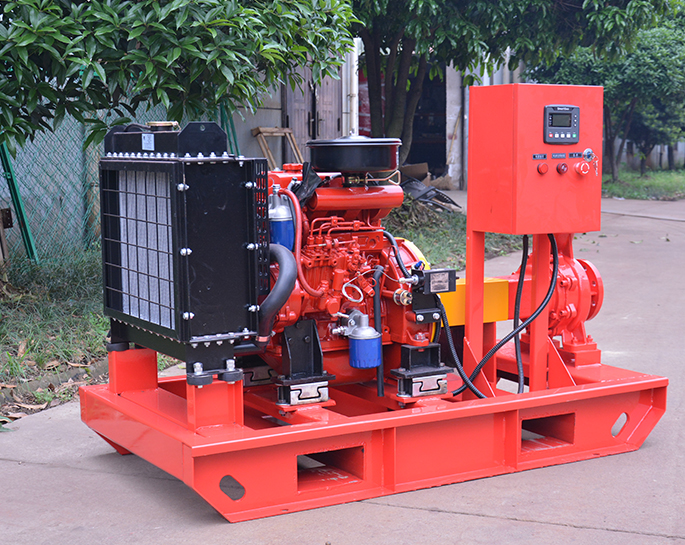

Diesel engine fire pumps play a crucial role in ensuring the safety of lives and property during emergencies. These powerful devices provide a reliable source of water for fire suppression systems, making them an essential component of fire protection infrastructure. However, it is vital to pay close attention to certain factors when using diesel engine fire pumps to ensure their efficient and safe operation. This essay explores key considerations that should be kept in mind to maximize the effectiveness and reliability of diesel engine fire pumps.

Regular Maintenance:

One of the primary aspects to focus on when using diesel engine fire pumps is regular maintenance. Routine inspections, servicing, and preventive maintenance are essential to keep the pumps in optimal condition. It is crucial to follow the manufacturer's recommendations regarding maintenance schedules, oil changes, fuel filter replacements, and overall system checks. Neglecting maintenance can result in decreased performance, increased fuel consumption, and even pump failure during critical situations.

Fuel Quality and Storage:

Diesel engine fire pumps rely on high-quality fuel to function efficiently. It is crucial to use clean, contaminant-free diesel fuel to avoid clogging the system or causing engine malfunctions. Regularly inspect and clean the fuel tank, and ensure proper filtration to prevent impurities from entering the engine. Additionally, attention should be given to the storage conditions of the fuel, including temperature control and protection from water or moisture intrusion.

Proper Ventilation:

Proper ventilation is essential for diesel engine fire pumps to operate effectively. These engines produce exhaust gases that contain harmful substances, such as carbon monoxide. Adequate ventilation helps dissipate these gases and prevents the buildup of toxic fumes in the pump room. Ensure that the pump room has sufficient air exchange, proper exhaust systems, and adheres to local regulations for ventilation standards to safeguard the health and safety of personnel.

Regular Testing and Training:

Regular testing and training are crucial for diesel engine fire pumps. Conducting periodic performance tests ensures that the pumps are functioning within acceptable parameters. This includes testing the pump's flow rate, pressure, and suction capabilities. Moreover, training personnel on the correct operation and maintenance procedures is vital to ensure their competence and familiarity with emergency protocols. This proactive approach enhances the response time and effectiveness of the fire suppression system when the need arises.

Backup Systems and Redundancy:

To ensure uninterrupted fire protection, it is important to have backup systems and redundancy in place. Diesel engine fire pumps should be equipped with backup power sources, such as generators or battery systems, to mitigate the risk of power failures during emergencies. Additionally, having redundant fire pumps installed can serve as a fail-safe mechanism, providing backup in case of pump failure or maintenance requirements. Regularly test and maintain these backup systems to ensure their reliability when needed.

Conclusion:

Diesel engine fire pumps are crucial for effective fire suppression systems, and paying attention to specific factors can significantly enhance their reliability and performance. Regular maintenance, fuel quality and storage, proper ventilation, regular testing and training, and the presence of backup systems are key considerations to prioritize. By adhering to these guidelines, fire protection systems can be confidently relied upon during critical situations, protecting lives and property effectively.