What role do check valves play in a fire pump system, and how often should they be inspected?

Dec 26, 2023

Share:

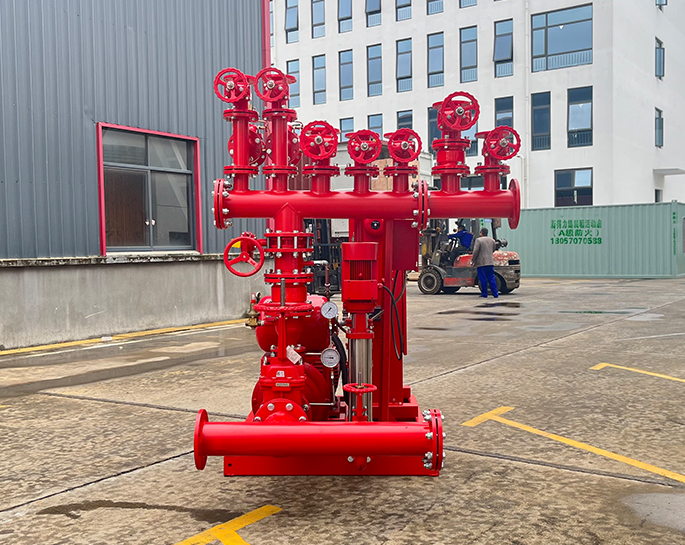

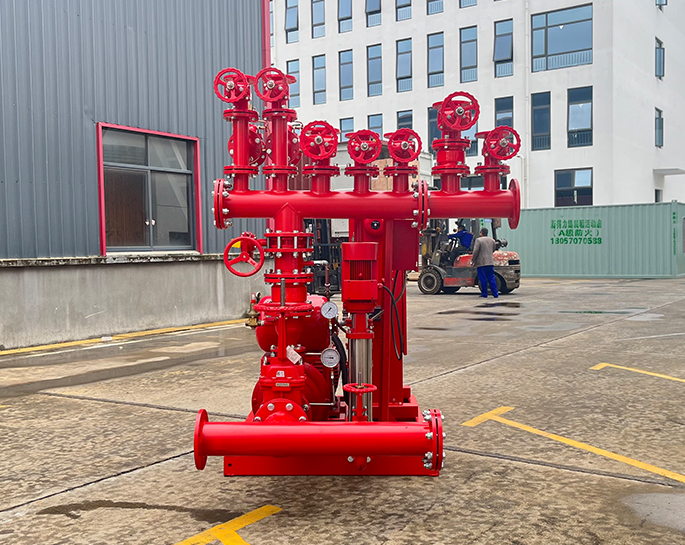

Check valves play a crucial role in a fire pump system by preventing the reverse flow of water when the pump is not in operation. They are typically installed on the discharge side of the pump and are essential for maintaining system pressure and preventing backflow. The primary functions of check valves in a fire pump system include:

1. **Backflow Prevention:**

Check valves ensure that water flows in the intended direction, preventing reverse flow when the pump is not actively operating. This helps maintain pressure in the system and ensures that water is readily available for firefighting purposes.

2. **System Integrity:**

Check valves contribute to the overall integrity of the fire pump system by preventing the loss of prime (water) in the suction piping and pump when the pump is not running. This ensures that the pump is ready to operate immediately when needed.

3. **Compliance with Codes and Standards:**

Fire pump systems are subject to various codes and standards, such as the National Fire Protection Association (NFPA) standards. These codes often mandate the installation of check valves to meet specific requirements for the proper design and operation of fire protection systems.

As for inspection frequency, it is essential to follow the manufacturer's recommendations and industry standards, such as NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems). Generally, check valves should be inspected and tested regularly to ensure their proper functioning. The frequency of inspections may vary based on factors such as the type of check valve, environmental conditions, and local regulations.

NFPA 25 recommends that check valves be visually inspected on a weekly or monthly basis and tested annually. During inspections, look for signs of physical damage, corrosion, or any other issues that could affect the performance of the check valve. Regular testing involves ensuring that the check valve opens and closes properly and that there are no leaks.

It's important to note that inspection and testing requirements may vary, so it's crucial to consult the specific guidelines provided by the manufacturer of the check valve and any applicable local codes and standards. Additionally, a qualified fire protection professional or technician should perform these inspections and tests to ensure compliance and the proper functioning of the fire pump system.

1. **Backflow Prevention:**

Check valves ensure that water flows in the intended direction, preventing reverse flow when the pump is not actively operating. This helps maintain pressure in the system and ensures that water is readily available for firefighting purposes.

2. **System Integrity:**

Check valves contribute to the overall integrity of the fire pump system by preventing the loss of prime (water) in the suction piping and pump when the pump is not running. This ensures that the pump is ready to operate immediately when needed.

3. **Compliance with Codes and Standards:**

Fire pump systems are subject to various codes and standards, such as the National Fire Protection Association (NFPA) standards. These codes often mandate the installation of check valves to meet specific requirements for the proper design and operation of fire protection systems.

As for inspection frequency, it is essential to follow the manufacturer's recommendations and industry standards, such as NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems). Generally, check valves should be inspected and tested regularly to ensure their proper functioning. The frequency of inspections may vary based on factors such as the type of check valve, environmental conditions, and local regulations.

NFPA 25 recommends that check valves be visually inspected on a weekly or monthly basis and tested annually. During inspections, look for signs of physical damage, corrosion, or any other issues that could affect the performance of the check valve. Regular testing involves ensuring that the check valve opens and closes properly and that there are no leaks.

It's important to note that inspection and testing requirements may vary, so it's crucial to consult the specific guidelines provided by the manufacturer of the check valve and any applicable local codes and standards. Additionally, a qualified fire protection professional or technician should perform these inspections and tests to ensure compliance and the proper functioning of the fire pump system.