What is the impact of altitude on fire pump performance?

Aug 13, 2024

Share:

Altitude can significantly affect the performance of fire pumps due to changes in air pressure and density. Here’s how altitude impacts fire pump performance:

### 1. **Reduced Air Pressure and Oxygen Availability**

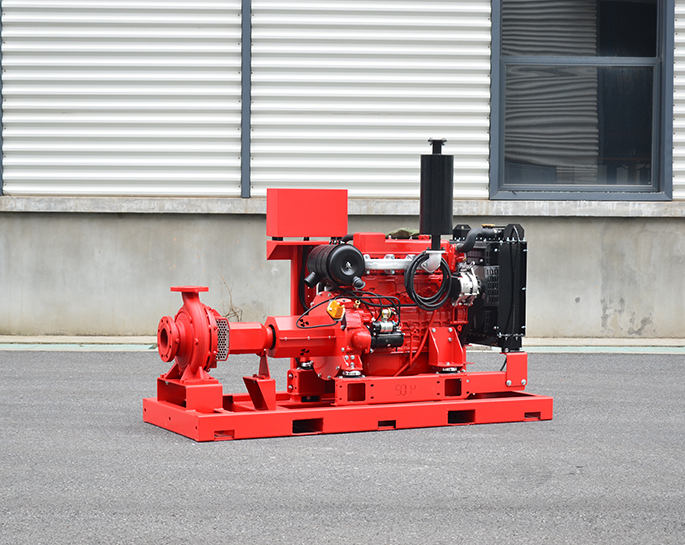

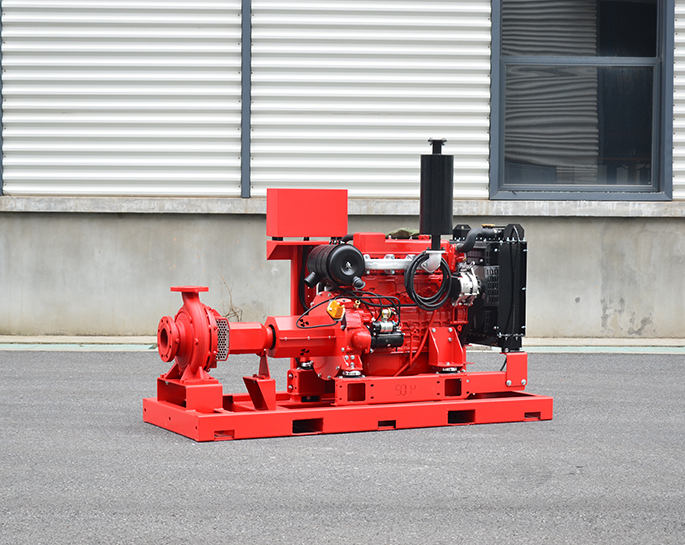

- **Diesel Engine Fire Pumps**: At higher altitudes, the air pressure is lower, which means there is less oxygen available for combustion in diesel engines. This can lead to a reduction in engine power, which in turn can decrease the pump's ability to achieve its designed flow and pressure. Manufacturers often provide derating factors for engines operating at higher altitudes.

- **Electric Fire Pumps**: While electric motors are less directly affected by altitude, they may still experience reduced performance if the cooling system is air-based. Lower air density reduces cooling efficiency, which can cause the motor to overheat and operate less efficiently.

### 2. **Impact on Suction Pressure**

- **NPSH (Net Positive Suction Head)**: Altitude reduces atmospheric pressure, which decreases the Net Positive Suction Head Available (NPSHA). This can cause cavitation, where vapor bubbles form in the pump, leading to reduced performance, efficiency loss, and potential damage to the pump components.

- **Pump Selection**: For installations at higher altitudes, it’s crucial to select pumps that can operate effectively with the reduced NPSHA. This may require choosing a pump with a lower NPSH requirement or making adjustments to the system design, such as using a booster pump.

### 3. **Temperature Considerations**

- **Cooling and Lubrication**: Both electric and diesel pumps rely on proper cooling and lubrication for optimal performance. At higher altitudes, the cooling effect of air is reduced, which can lead to higher operating temperatures. Ensuring proper cooling mechanisms are in place is critical to maintain pump performance.

### 4. **Manufacturer Guidelines**

- **Derating**: Most pump and engine manufacturers provide specific derating guidelines for high-altitude applications. This typically involves reducing the pump’s capacity or pressure output to account for the reduced performance of the engine or motor at higher altitudes.

In summary, when installing fire pumps at higher altitudes, it's essential to account for the reduced air pressure and its impact on both the engine/motor and the hydraulic aspects of the pump system. Proper selection, derating, and system design modifications are necessary to ensure reliable and efficient operation.

### 1. **Reduced Air Pressure and Oxygen Availability**

- **Diesel Engine Fire Pumps**: At higher altitudes, the air pressure is lower, which means there is less oxygen available for combustion in diesel engines. This can lead to a reduction in engine power, which in turn can decrease the pump's ability to achieve its designed flow and pressure. Manufacturers often provide derating factors for engines operating at higher altitudes.

- **Electric Fire Pumps**: While electric motors are less directly affected by altitude, they may still experience reduced performance if the cooling system is air-based. Lower air density reduces cooling efficiency, which can cause the motor to overheat and operate less efficiently.

### 2. **Impact on Suction Pressure**

- **NPSH (Net Positive Suction Head)**: Altitude reduces atmospheric pressure, which decreases the Net Positive Suction Head Available (NPSHA). This can cause cavitation, where vapor bubbles form in the pump, leading to reduced performance, efficiency loss, and potential damage to the pump components.

- **Pump Selection**: For installations at higher altitudes, it’s crucial to select pumps that can operate effectively with the reduced NPSHA. This may require choosing a pump with a lower NPSH requirement or making adjustments to the system design, such as using a booster pump.

### 3. **Temperature Considerations**

- **Cooling and Lubrication**: Both electric and diesel pumps rely on proper cooling and lubrication for optimal performance. At higher altitudes, the cooling effect of air is reduced, which can lead to higher operating temperatures. Ensuring proper cooling mechanisms are in place is critical to maintain pump performance.

### 4. **Manufacturer Guidelines**

- **Derating**: Most pump and engine manufacturers provide specific derating guidelines for high-altitude applications. This typically involves reducing the pump’s capacity or pressure output to account for the reduced performance of the engine or motor at higher altitudes.

In summary, when installing fire pumps at higher altitudes, it's essential to account for the reduced air pressure and its impact on both the engine/motor and the hydraulic aspects of the pump system. Proper selection, derating, and system design modifications are necessary to ensure reliable and efficient operation.

.png)

.png)

.png)