What is the difference between a split-case fire pump and an end-suction fire pump?

Jan 19, 2024

Share:

The main differences between split-case fire pumps and end-suction fire pumps lie in their design and configuration. Both types of pumps are commonly used for firefighting applications, but they have distinct characteristics. Here's a brief overview of the key differences:

1. **Design:**

- **Split-Case Fire Pump:**

- The split-case fire pump, as the name suggests, has a horizontally split casing. This means that the pump casing is divided into two parts along a horizontal plane.

- The split-case design allows for easy access to the internal components, simplifying maintenance and repair.

- These pumps typically have a larger footprint compared to end-suction pumps.

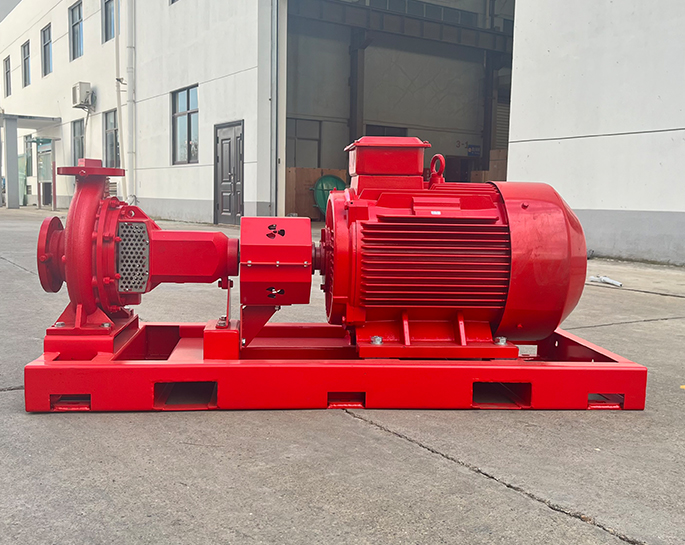

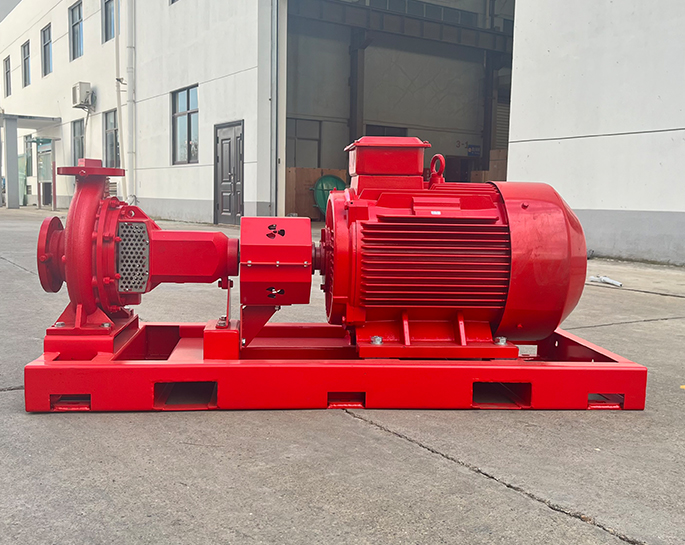

- **End-Suction Fire Pump:**

- The end-suction fire pump has a single casing that covers the entire pump assembly.

- It is a more compact design compared to split-case pumps.

- Accessing internal components for maintenance may require disassembling the pump casing.

2. **Impeller Configuration:**

- **Split-Case Fire Pump:**

- Split-case pumps usually have a double-suction impeller. This means that the impeller draws water into the pump from both sides.

- The double-suction design helps balance axial thrust and provides better hydraulic efficiency.

- **End-Suction Fire Pump:**

- End-suction pumps typically have a single-suction impeller, drawing water from one side of the impeller.

- Single-suction impellers are simpler in design and may be more cost-effective.

3. **Application and Flow Rate:**

- **Split-Case Fire Pump:**

- Split-case pumps are often preferred for higher flow rate applications.

- They are suitable for situations where a large volume of water needs to be moved efficiently.

- **End-Suction Fire Pump:**

- End-suction pumps are commonly used for applications with lower to moderate flow rates.

- They are versatile and can handle a range of flow requirements.

4. **Efficiency:**

- **Split-Case Fire Pump:**

- The design of split-case pumps, especially with double-suction impellers, can contribute to higher hydraulic efficiency.

- **End-Suction Fire Pump:**

- While end-suction pumps may have slightly lower hydraulic efficiency compared to split-case pumps, they are still effective for various applications.

The choice between a split-case and an end-suction fire pump depends on factors such as the specific requirements of the firefighting system, available space, budget considerations, and maintenance preferences. Consulting with a fire protection engineer or pump specialist can help determine the most suitable pump for a given application.

1. **Design:**

- **Split-Case Fire Pump:**

- The split-case fire pump, as the name suggests, has a horizontally split casing. This means that the pump casing is divided into two parts along a horizontal plane.

- The split-case design allows for easy access to the internal components, simplifying maintenance and repair.

- These pumps typically have a larger footprint compared to end-suction pumps.

- **End-Suction Fire Pump:**

- The end-suction fire pump has a single casing that covers the entire pump assembly.

- It is a more compact design compared to split-case pumps.

- Accessing internal components for maintenance may require disassembling the pump casing.

2. **Impeller Configuration:**

- **Split-Case Fire Pump:**

- Split-case pumps usually have a double-suction impeller. This means that the impeller draws water into the pump from both sides.

- The double-suction design helps balance axial thrust and provides better hydraulic efficiency.

- **End-Suction Fire Pump:**

- End-suction pumps typically have a single-suction impeller, drawing water from one side of the impeller.

- Single-suction impellers are simpler in design and may be more cost-effective.

3. **Application and Flow Rate:**

- **Split-Case Fire Pump:**

- Split-case pumps are often preferred for higher flow rate applications.

- They are suitable for situations where a large volume of water needs to be moved efficiently.

- **End-Suction Fire Pump:**

- End-suction pumps are commonly used for applications with lower to moderate flow rates.

- They are versatile and can handle a range of flow requirements.

4. **Efficiency:**

- **Split-Case Fire Pump:**

- The design of split-case pumps, especially with double-suction impellers, can contribute to higher hydraulic efficiency.

- **End-Suction Fire Pump:**

- While end-suction pumps may have slightly lower hydraulic efficiency compared to split-case pumps, they are still effective for various applications.

The choice between a split-case and an end-suction fire pump depends on factors such as the specific requirements of the firefighting system, available space, budget considerations, and maintenance preferences. Consulting with a fire protection engineer or pump specialist can help determine the most suitable pump for a given application.

.png)

.png)

.png)