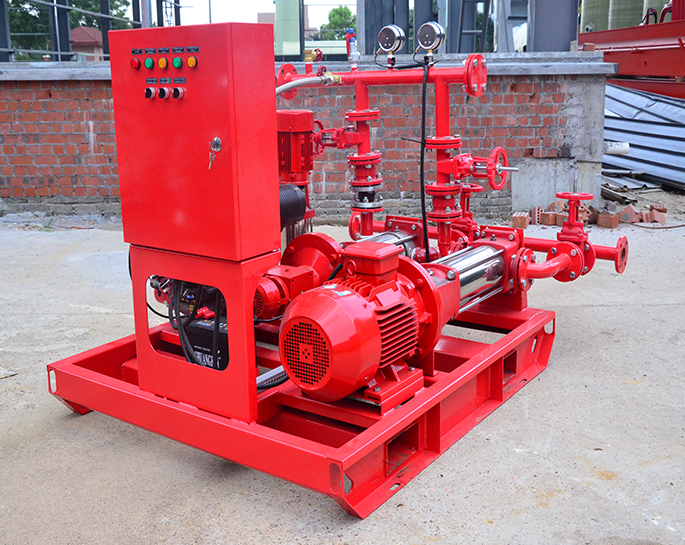

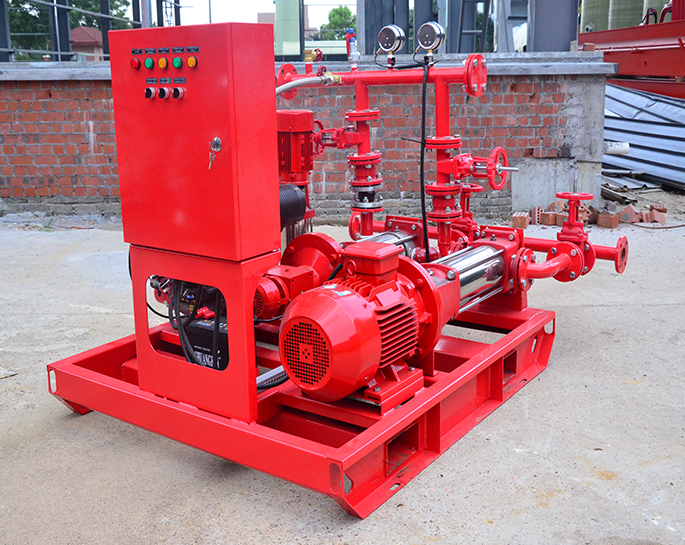

What are the safety considerations when operating a diesel fire pump?

Mar 11, 2024

Share:

Operating a diesel fire pump requires careful attention to safety considerations to ensure the safety of personnel and effective response to fire emergencies. Here are some key safety considerations:

1. **Training and Familiarization**: All personnel involved in operating the diesel fire pump should be adequately trained and familiarized with the equipment. They should understand its operation, maintenance procedures, and safety protocols.

2. **Personal Protective Equipment (PPE)**: Operators should wear appropriate PPE, including protective clothing, gloves, safety goggles, and hearing protection, if necessary.

3. **Ventilation**: Ensure proper ventilation in the area where the diesel fire pump is operating to prevent the buildup of exhaust fumes and maintain a safe working environment.

4. **Fuel Handling**: Handle diesel fuel carefully to prevent spills and minimize the risk of fire or environmental contamination. Follow proper procedures for fueling the pump, including using approved containers and maintaining spill containment measures.

5. **Engine Exhaust**: Position the diesel fire pump in a location where engine exhaust gases will not pose a risk to personnel. Avoid operating the pump in confined spaces without adequate ventilation.

6. **Fire Hazards**: Be aware of potential fire hazards in the vicinity of the diesel fire pump, such as flammable materials or ignition sources. Keep the area clear of debris and other combustible materials.

7. **Emergency Shutdown Procedures**: Ensure that operators are familiar with emergency shutdown procedures in case of equipment malfunction or other emergencies. This may include shutting off fuel and electrical power to the pump.

8. **Regular Maintenance**: Perform regular maintenance and inspections of the diesel fire pump according to manufacturer recommendations. This includes checking for leaks, inspecting hoses and fittings, and verifying proper engine operation.

9. **Fire Response Plan**: Have a comprehensive fire response plan in place that includes procedures for operating the diesel fire pump effectively during a fire emergency. Ensure that all personnel are trained on their roles and responsibilities in implementing the plan.

10. **Communication**: Maintain clear communication among operators and other personnel involved in fire response activities. Use radios or other communication devices to coordinate actions and relay important information.

By adhering to these safety considerations, operators can minimize risks and ensure the safe and effective operation of diesel fire pumps during fire emergencies.

1. **Training and Familiarization**: All personnel involved in operating the diesel fire pump should be adequately trained and familiarized with the equipment. They should understand its operation, maintenance procedures, and safety protocols.

2. **Personal Protective Equipment (PPE)**: Operators should wear appropriate PPE, including protective clothing, gloves, safety goggles, and hearing protection, if necessary.

3. **Ventilation**: Ensure proper ventilation in the area where the diesel fire pump is operating to prevent the buildup of exhaust fumes and maintain a safe working environment.

4. **Fuel Handling**: Handle diesel fuel carefully to prevent spills and minimize the risk of fire or environmental contamination. Follow proper procedures for fueling the pump, including using approved containers and maintaining spill containment measures.

5. **Engine Exhaust**: Position the diesel fire pump in a location where engine exhaust gases will not pose a risk to personnel. Avoid operating the pump in confined spaces without adequate ventilation.

6. **Fire Hazards**: Be aware of potential fire hazards in the vicinity of the diesel fire pump, such as flammable materials or ignition sources. Keep the area clear of debris and other combustible materials.

7. **Emergency Shutdown Procedures**: Ensure that operators are familiar with emergency shutdown procedures in case of equipment malfunction or other emergencies. This may include shutting off fuel and electrical power to the pump.

8. **Regular Maintenance**: Perform regular maintenance and inspections of the diesel fire pump according to manufacturer recommendations. This includes checking for leaks, inspecting hoses and fittings, and verifying proper engine operation.

9. **Fire Response Plan**: Have a comprehensive fire response plan in place that includes procedures for operating the diesel fire pump effectively during a fire emergency. Ensure that all personnel are trained on their roles and responsibilities in implementing the plan.

10. **Communication**: Maintain clear communication among operators and other personnel involved in fire response activities. Use radios or other communication devices to coordinate actions and relay important information.

By adhering to these safety considerations, operators can minimize risks and ensure the safe and effective operation of diesel fire pumps during fire emergencies.