How to Choose Fire Pumps for Large-Scale Manufacturing Facilities

Nov 05, 2024

Share:

Choosing the right fire pumps for large-scale manufacturing facilities involves careful consideration of the facility's unique fire protection needs, including the size of the facility, fire hazard classifications, water supply requirements, and regulatory standards. Here’s a guide on selecting the best fire pump for such applications:

1. Understand Facility Requirements

- Size of the Facility: Large manufacturing facilities typically require high-capacity pumps that can deliver large volumes of water to cover extensive areas quickly.

- Fire Hazard Classification: Different manufacturing processes may involve flammable materials, impacting the fire hazard classification and, therefore, the type of fire pump needed.

- Water Supply: Ensure your facility has adequate water supply, whether from a municipal source, reservoir, or tanks, to support the fire pump’s water demand.

2. Evaluate Pump Types and Configurations

- Electric vs. Diesel Fire Pumps:

- Electric Fire Pumps are ideal for facilities with a reliable power source. They’re generally quieter, more energy-efficient, and easier to maintain.

- Diesel Engine Fire Pumps are a good choice if you need a backup power source for your fire system, as they operate independently of the electrical grid.

- Jockey Pumps: These smaller pumps maintain pressure in the fire protection system and reduce wear on the primary fire pump, which is essential in large facilities with extensive piping networks.

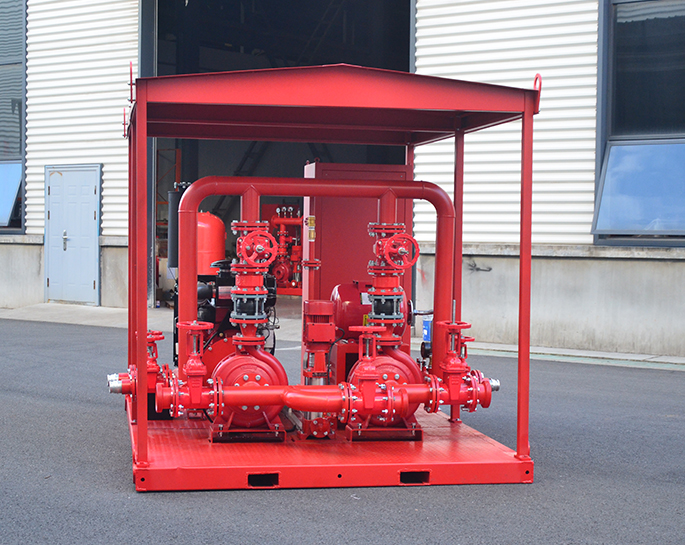

- Combined Fire Pump Packages: Pre-assembled UL-listed and NFPA20-compliant packages simplify installation and maintenance, making them suitable for large-scale operations.

3. Consider Flow Rate and Pressure Requirements

- Fire pumps for large facilities need to deliver higher flow rates and pressures to cover the entire area. Look at factors such as required flow (gallons per minute, GPM) and pressure (psi), ensuring the pump can meet the NFPA20 standards for fire protection.

4. Look for UL/FM Certifications

- Choose pumps that are UL-listed and FM-approved, as these certifications ensure compliance with industry safety standards. This is especially important in manufacturing settings where compliance can impact insurance and operational licenses.

5. Factor in Environmental and Operational Conditions

- Climate: For facilities in harsh weather environments, you may need pumps with special enclosures or heating features.

- Maintenance Accessibility: Large facilities may require pumps that are easily accessible for regular maintenance to ensure reliable performance.

- Noise Control: Consider if noise restrictions apply in your facility, as diesel engines tend to be louder than electric pumps.

6. Ensure Compliance with NFPA20 Standards

- NFPA20 standards outline fire pump requirements, including installation, testing, and maintenance. Partner with a supplier that can provide UL-listed and NFPA20-compliant fire pumps to ensure your setup meets safety regulations.

7. Consider Working with Experienced Suppliers

- Partnering with a supplier who understands the unique demands of large-scale facilities can be invaluable. Look for a provider with extensive experience and a range of products, from high-capacity diesel and electric fire pumps to complete package sets, to ensure you get a customized solution that fits your needs.

Would you like suggestions for specific models or configurations for a particular type of manufacturing facility?

.png)

.png)

.png)