How do fire pumps operate in cold storage facilities?

Aug 21, 2024

Share:

Fire pumps in cold storage facilities play a critical role in ensuring fire protection, even in environments with low temperatures. Here’s how they typically operate in these settings:

### 1. **Heat Tracing and Insulation**

- **Piping:** In cold storage facilities, the fire protection piping is usually insulated and equipped with heat tracing to prevent freezing. This ensures that water can flow freely when needed, even in freezing temperatures.

- **Pump Room:** The room housing the fire pump is kept heated to maintain the pump and other components at a temperature above freezing.

### 2. **Anti-Freeze Loops**

- **Glycol Systems:** Sometimes, an anti-freeze loop filled with a glycol solution is used in areas where water in the pipes might freeze. This solution prevents freezing and ensures that the fire protection system remains operational.

### 3. **Dry Pipe Sprinkler Systems**

- **Dry Pipe Systems:** Cold storage facilities often use dry pipe sprinkler systems. These systems keep water out of the pipes until a fire is detected. Once activated, the fire pump quickly pressurizes the system, pushing water through to the sprinklers.

### 4. **Pre-Action Systems**

- **Two-Step Activation:** In some cases, pre-action systems are used. These require two triggers (like heat detection and a manual pull station) before water is released into the pipes. This setup helps prevent accidental discharge, which is crucial in environments like cold storage where water damage could ruin stored goods.

### 5. **Maintaining Water Flow**

- **Jockey Pumps:** Jockey pumps are used to maintain system pressure and compensate for minor leaks in the system, ensuring that the main fire pump doesn't need to activate unnecessarily.

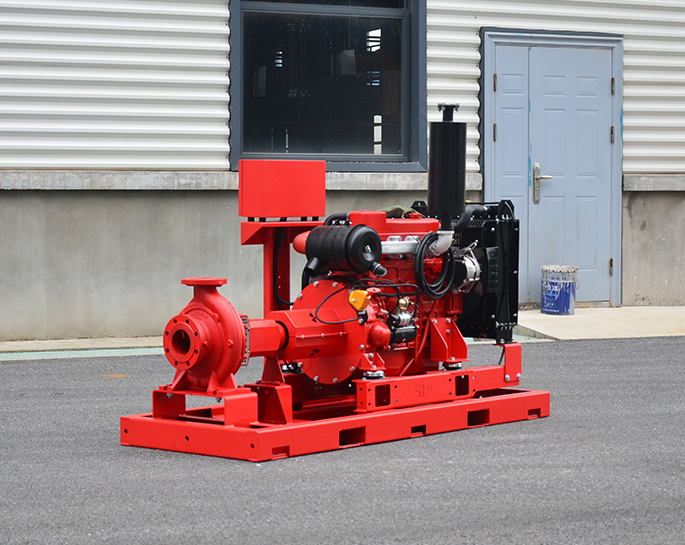

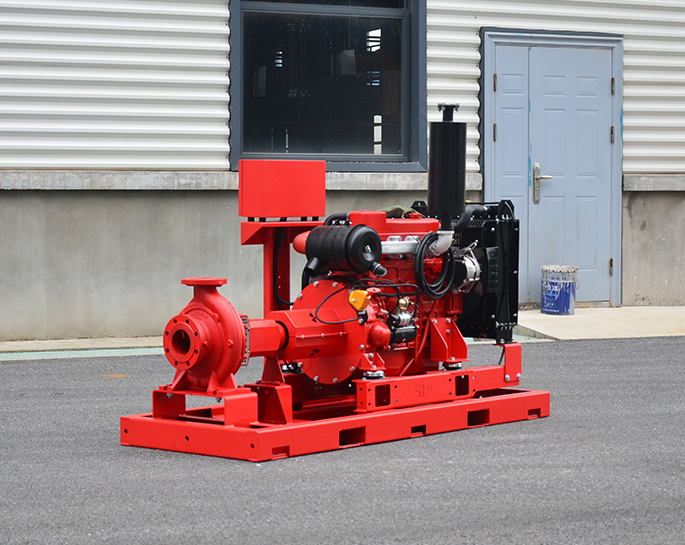

- **Diesel or Electric Pumps:** Depending on the facility, either diesel or electric fire pumps will be used. These pumps are ready to kick in immediately if there's a drop in pressure or if a fire is detected.

### 6. **Monitoring and Maintenance**

- **Regular Testing:** In cold storage facilities, fire pumps and the overall fire protection system are regularly tested and maintained to ensure that everything operates correctly, even in the extreme cold.

### 7. **Emergency Power Supply**

- **Backup Power:** Cold storage facilities often have backup power systems to ensure that the fire pump can operate even during a power outage, which is critical for maintaining fire protection.

These features help ensure that fire pumps in cold storage facilities are effective and reliable, even in challenging low-temperature environments.

### 1. **Heat Tracing and Insulation**

- **Piping:** In cold storage facilities, the fire protection piping is usually insulated and equipped with heat tracing to prevent freezing. This ensures that water can flow freely when needed, even in freezing temperatures.

- **Pump Room:** The room housing the fire pump is kept heated to maintain the pump and other components at a temperature above freezing.

### 2. **Anti-Freeze Loops**

- **Glycol Systems:** Sometimes, an anti-freeze loop filled with a glycol solution is used in areas where water in the pipes might freeze. This solution prevents freezing and ensures that the fire protection system remains operational.

### 3. **Dry Pipe Sprinkler Systems**

- **Dry Pipe Systems:** Cold storage facilities often use dry pipe sprinkler systems. These systems keep water out of the pipes until a fire is detected. Once activated, the fire pump quickly pressurizes the system, pushing water through to the sprinklers.

### 4. **Pre-Action Systems**

- **Two-Step Activation:** In some cases, pre-action systems are used. These require two triggers (like heat detection and a manual pull station) before water is released into the pipes. This setup helps prevent accidental discharge, which is crucial in environments like cold storage where water damage could ruin stored goods.

### 5. **Maintaining Water Flow**

- **Jockey Pumps:** Jockey pumps are used to maintain system pressure and compensate for minor leaks in the system, ensuring that the main fire pump doesn't need to activate unnecessarily.

- **Diesel or Electric Pumps:** Depending on the facility, either diesel or electric fire pumps will be used. These pumps are ready to kick in immediately if there's a drop in pressure or if a fire is detected.

### 6. **Monitoring and Maintenance**

- **Regular Testing:** In cold storage facilities, fire pumps and the overall fire protection system are regularly tested and maintained to ensure that everything operates correctly, even in the extreme cold.

### 7. **Emergency Power Supply**

- **Backup Power:** Cold storage facilities often have backup power systems to ensure that the fire pump can operate even during a power outage, which is critical for maintaining fire protection.

These features help ensure that fire pumps in cold storage facilities are effective and reliable, even in challenging low-temperature environments.