How do fire pump systems handle redundancy and reliability in critical infrastructure?

Jun 11, 2024

Share:

Fire pump systems handle redundancy and reliability in critical infrastructure through several key strategies and components. Here are the primary ways they ensure these critical requirements:

### 1. Multiple Pump Configurations

**a. **Multiple Pump Types:**

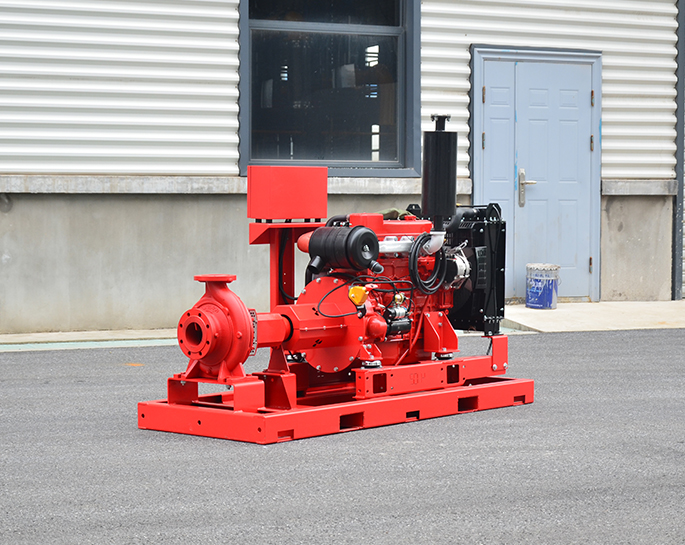

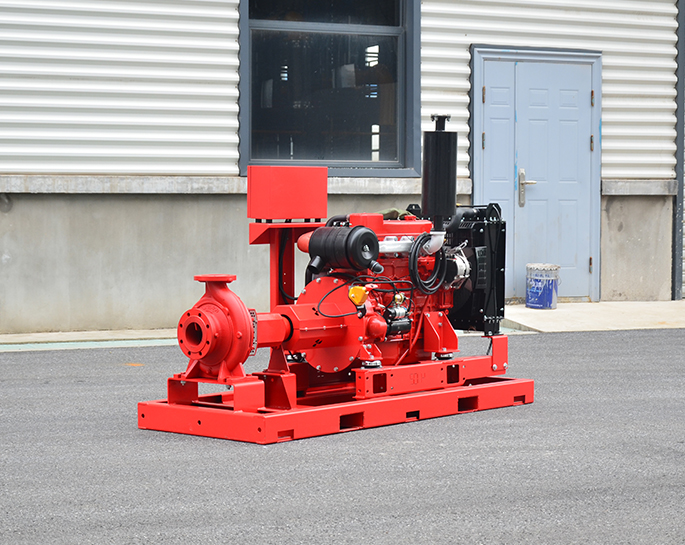

- **Electric and Diesel Pumps:** To ensure operation during a power outage, systems often include both electric motor-driven pumps and diesel engine-driven pumps. The diesel pump serves as a backup in case of electrical failure.

- **Jockey Pumps:** These are smaller pumps that maintain system pressure and prevent the main pumps from cycling on and off due to minor pressure drops.

**b. **Parallel Pumps:**

- Systems may have multiple pumps arranged in parallel to handle peak demand or in case one pump fails. This configuration allows one pump to take over if another becomes inoperative.

### 2. Automatic Transfer Switches (ATS)

- **Switching Power Sources:** For electric-driven pumps, an ATS can switch the power supply from the primary source to a backup generator automatically if the main power fails, ensuring continuous operation.

### 3. Redundant Power Supplies

- **Dual Electrical Feeds:** Some critical systems may have two independent electrical feeds to the pump house, reducing the likelihood of a complete power loss.

- **Backup Generators:** In addition to diesel pumps, backup generators can provide power to electric pumps if the main power supply is interrupted.

### 4. Comprehensive Control and Monitoring Systems

- **Control Panels:** These include sophisticated control panels that can automatically start backup pumps and switch power sources.

- **Alarm Systems:** Integrated alarm systems notify personnel of any pump failure, abnormal pressure conditions, or power issues, enabling quick response.

- **Remote Monitoring:** Advanced systems allow for remote monitoring and control, ensuring that any issues are detected and addressed promptly.

### 5. Regular Maintenance and Testing

- **Routine Inspections:** Regular inspections and maintenance of pumps, controllers, and power supplies are critical to ensuring reliability.

- **Periodic Testing:** Fire pumps should be tested regularly under load conditions to confirm their functionality. This includes weekly churn tests and annual flow tests.

### 6. Designed for Reliability

- **Robust Construction:** Pumps and components are built to meet stringent standards (e.g., NFPA 20) for durability and reliability.

- **Separation of Components:** Physical separation of redundant components (e.g., electric and diesel pumps) can prevent a single event (like a fire in the pump room) from disabling the entire system.

### 7. Compliance with Standards

- **NFPA Standards:** Compliance with National Fire Protection Association (NFPA) standards, particularly NFPA 20, which provides guidelines for the installation of stationary pumps for fire protection.

- **Local Regulations:** Adhering to local fire codes and standards, which may have additional requirements for redundancy and reliability.

### 8. Diverse Water Sources

- **Multiple Water Supplies:** Having multiple water sources (e.g., municipal water supply, dedicated fire water tanks, reservoirs) ensures that the system has an adequate supply of water even if one source is compromised.

By implementing these strategies, fire pump systems in critical infrastructure can achieve high levels of redundancy and reliability, ensuring that they perform effectively in emergencies.

### 1. Multiple Pump Configurations

**a. **Multiple Pump Types:**

- **Electric and Diesel Pumps:** To ensure operation during a power outage, systems often include both electric motor-driven pumps and diesel engine-driven pumps. The diesel pump serves as a backup in case of electrical failure.

- **Jockey Pumps:** These are smaller pumps that maintain system pressure and prevent the main pumps from cycling on and off due to minor pressure drops.

**b. **Parallel Pumps:**

- Systems may have multiple pumps arranged in parallel to handle peak demand or in case one pump fails. This configuration allows one pump to take over if another becomes inoperative.

### 2. Automatic Transfer Switches (ATS)

- **Switching Power Sources:** For electric-driven pumps, an ATS can switch the power supply from the primary source to a backup generator automatically if the main power fails, ensuring continuous operation.

### 3. Redundant Power Supplies

- **Dual Electrical Feeds:** Some critical systems may have two independent electrical feeds to the pump house, reducing the likelihood of a complete power loss.

- **Backup Generators:** In addition to diesel pumps, backup generators can provide power to electric pumps if the main power supply is interrupted.

### 4. Comprehensive Control and Monitoring Systems

- **Control Panels:** These include sophisticated control panels that can automatically start backup pumps and switch power sources.

- **Alarm Systems:** Integrated alarm systems notify personnel of any pump failure, abnormal pressure conditions, or power issues, enabling quick response.

- **Remote Monitoring:** Advanced systems allow for remote monitoring and control, ensuring that any issues are detected and addressed promptly.

### 5. Regular Maintenance and Testing

- **Routine Inspections:** Regular inspections and maintenance of pumps, controllers, and power supplies are critical to ensuring reliability.

- **Periodic Testing:** Fire pumps should be tested regularly under load conditions to confirm their functionality. This includes weekly churn tests and annual flow tests.

### 6. Designed for Reliability

- **Robust Construction:** Pumps and components are built to meet stringent standards (e.g., NFPA 20) for durability and reliability.

- **Separation of Components:** Physical separation of redundant components (e.g., electric and diesel pumps) can prevent a single event (like a fire in the pump room) from disabling the entire system.

### 7. Compliance with Standards

- **NFPA Standards:** Compliance with National Fire Protection Association (NFPA) standards, particularly NFPA 20, which provides guidelines for the installation of stationary pumps for fire protection.

- **Local Regulations:** Adhering to local fire codes and standards, which may have additional requirements for redundancy and reliability.

### 8. Diverse Water Sources

- **Multiple Water Supplies:** Having multiple water sources (e.g., municipal water supply, dedicated fire water tanks, reservoirs) ensures that the system has an adequate supply of water even if one source is compromised.

By implementing these strategies, fire pump systems in critical infrastructure can achieve high levels of redundancy and reliability, ensuring that they perform effectively in emergencies.

.png)

.png)

.png)