Precautions for fire pump use

Sep 15, 2020

Share:

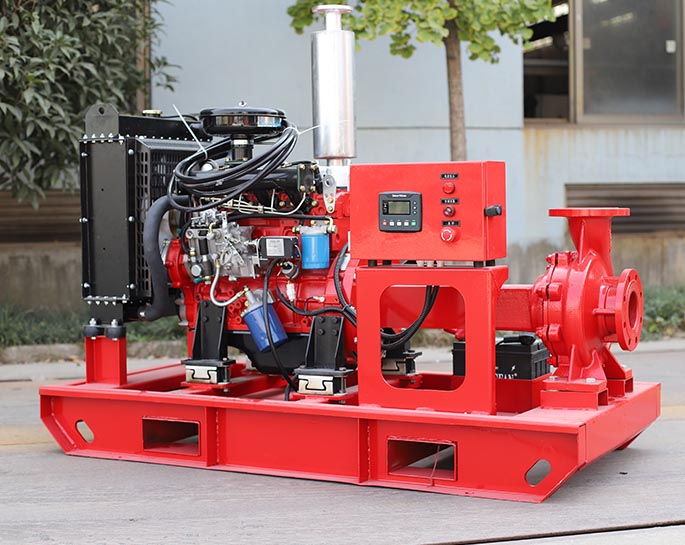

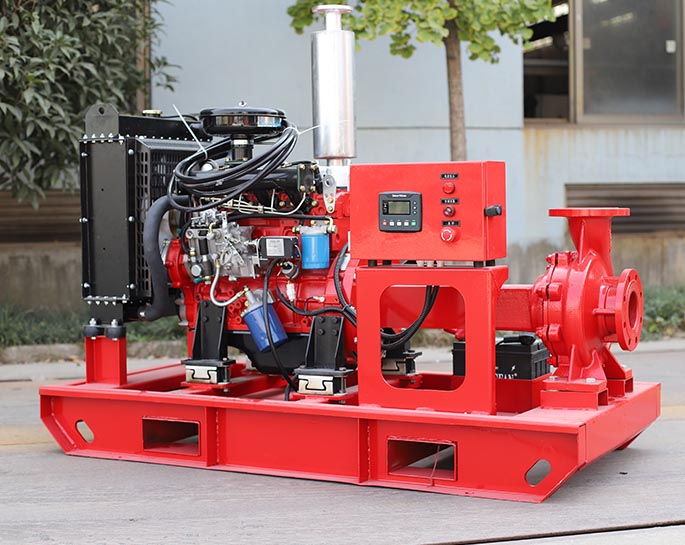

Fire pumps are pumps for fire protection. They are divided into different types according to different classification methods. They are widely used in environmental protection, water treatment, fire protection and other departments to pump all kinds of different types of liquid, is the ideal pump and fire protection system pump for creating leak-free, non-pollution civilized workshops and civilized factories. So, what should be paid attention to during the use of the fire pump?

1. The most common fault when the fire pump absorbs water is the air leak in the suction line.

2. The filter should be installed at the end of the suction pipe to avoid foreign matter.

3. The lubricating oil of the pump gearbox should be added to the oil line position shown by the oil plug.

4. Put the fire equipment such as pumps in a warm place in the cold season.

6. Make all the suction valve and drain valve flexible and convenient, and easy to operate the hydrant pump.

7. Do not let the fire pump run for a long time with the water outlet completely closed.

8. Pay attention to the engine temperature. When there is overheating signal, take corresponding measures.

9. Fire pumps that are not used frequently should be inspected and operated regularly to ensure emergency handling.

10. Unless the water is to be diverted immediately, do not let the fire pump operate without water.

11. Excessive suction pipe is unfavorable to the pump. In addition to increasing the friction loss and reducing the flow rate, cavitation will also occur.

12. When the pump absorbs water from ponds, rivers, lakes, etc., ensure that the water source is clean and separated from other debris.

13. Check the oil volume every 25 hours (or every 6 months) and change the oil every 50 hours (or every 12 months).

14. The end of the suction pipe should not be too close to the bottom of the water source, otherwise it is easy to be blocked, generally should have a distance of 0.3m.

15. After the fire pump is diverted, the engine should be gradually accelerated. Do not suddenly increase the throttle. Slow down when the engine is stopped.

16. The free end of the suction tube must be immersed in water to a suitable depth to prevent air from entering the pipe. Especially when the flow rate of the pump is large, it must be immersed in the required depth. When the immersion depth is small, air enters the pipe and a small vortex is formed on the water surface. When the pump is operating at maximum flow, the recommended minimum immersion depth is 4 times the pipe diameter. When it is not possible to have a proper immersion depth, a baffle is placed at the end of the suction pipe to prevent air from entering.

17. The fire pump should immediately open the drain valve drain water after each work, especially in the cold season. Don't forget to close the drain valve after draining the remaining water, otherwise it will cause the next water diversion failure.

1. The most common fault when the fire pump absorbs water is the air leak in the suction line.

2. The filter should be installed at the end of the suction pipe to avoid foreign matter.

3. The lubricating oil of the pump gearbox should be added to the oil line position shown by the oil plug.

4. Put the fire equipment such as pumps in a warm place in the cold season.

5. After pumping the brine, the pump should be cleaned immediately with clean water to avoid rust.

6. Make all the suction valve and drain valve flexible and convenient, and easy to operate the hydrant pump.

7. Do not let the fire pump run for a long time with the water outlet completely closed.

8. Pay attention to the engine temperature. When there is overheating signal, take corresponding measures.

9. Fire pumps that are not used frequently should be inspected and operated regularly to ensure emergency handling.

10. Unless the water is to be diverted immediately, do not let the fire pump operate without water.

11. Excessive suction pipe is unfavorable to the pump. In addition to increasing the friction loss and reducing the flow rate, cavitation will also occur.

12. When the pump absorbs water from ponds, rivers, lakes, etc., ensure that the water source is clean and separated from other debris.

13. Check the oil volume every 25 hours (or every 6 months) and change the oil every 50 hours (or every 12 months).

14. The end of the suction pipe should not be too close to the bottom of the water source, otherwise it is easy to be blocked, generally should have a distance of 0.3m.

15. After the fire pump is diverted, the engine should be gradually accelerated. Do not suddenly increase the throttle. Slow down when the engine is stopped.

16. The free end of the suction tube must be immersed in water to a suitable depth to prevent air from entering the pipe. Especially when the flow rate of the pump is large, it must be immersed in the required depth. When the immersion depth is small, air enters the pipe and a small vortex is formed on the water surface. When the pump is operating at maximum flow, the recommended minimum immersion depth is 4 times the pipe diameter. When it is not possible to have a proper immersion depth, a baffle is placed at the end of the suction pipe to prevent air from entering.

17. The fire pump should immediately open the drain valve drain water after each work, especially in the cold season. Don't forget to close the drain valve after draining the remaining water, otherwise it will cause the next water diversion failure.

.png)

.png)

.png)