Can Fire Pumps Withstand Harsh Environmental Conditions?

Here are some factors that help fire pumps perform reliably in challenging environments:

-

Corrosion Resistance: Pumps exposed to salty or humid environments (like coastal areas) are often made with corrosion-resistant materials, such as stainless steel or special coatings, to prevent rust and degradation.

-

Enclosures for Electrical Components: For electric fire pumps, the motors and control panels need to be housed in weatherproof or explosion-proof enclosures to protect them from moisture, dust, and extreme temperatures.

-

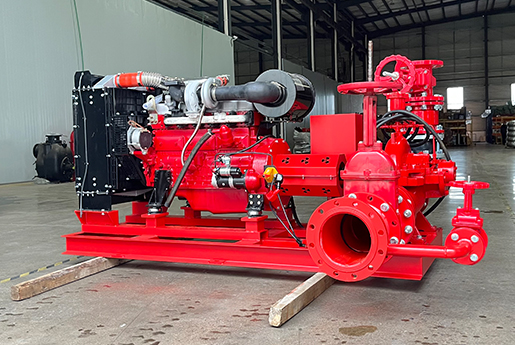

Diesel Engine Durability: Diesel-driven fire pumps can be more suitable for outdoor or remote installations where electricity might not be reliable. They can handle temperature variations better than some electric models and can be equipped with pre-heaters to ensure operation in cold climates.

-

Waterproofing and Sealing: Pumps installed in flood-prone or wet areas require waterproof seals to prevent water ingress, which could damage the internal components.

-

Temperature Ratings: Many fire pumps are rated to operate in extreme temperatures (both hot and cold), ensuring they can function in a variety of climates.

-

Vibration and Shock Resistance: For areas prone to earthquakes or other ground vibrations, fire pumps can be installed with vibration isolators or shock-absorbing mounts.

By considering these factors and choosing pumps with the right certifications (such as UL or NFPA20 compliance), you can ensure they are equipped to handle harsh conditions effectively.

.png)

.png)

.png)