The main components and characteristics of a fire pump

Nov 09, 2022

Share:

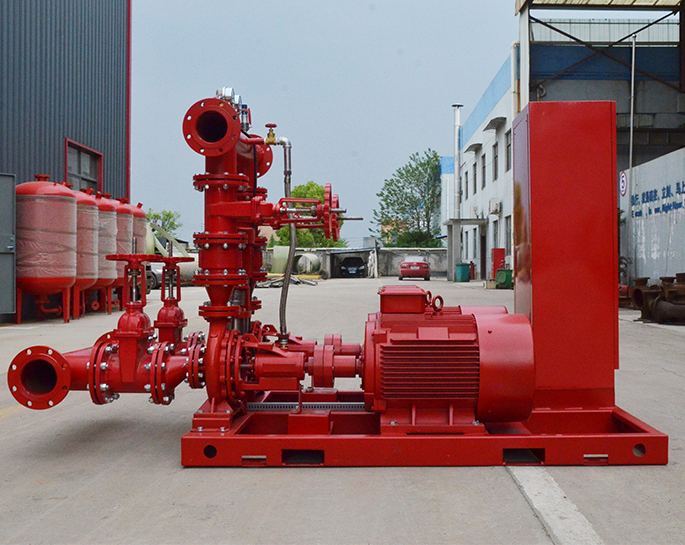

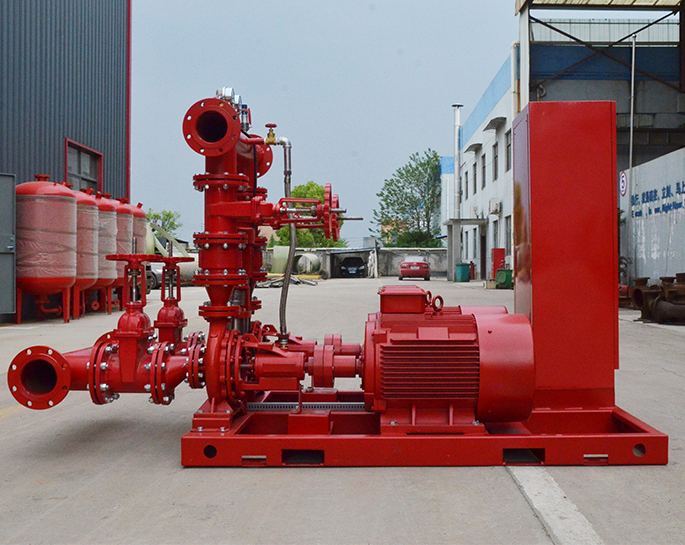

To understand the structure of fire pumps, it is helpful to buy, use and maintain fire pumps, so what parts do fire pumps consist of? Fire pumps are mainly composed of pump casing, impeller, pump shaft, sealing ring, bearings, etc. The following professional manufacturer of fire pumps zjbetter will talk about the role of these main components of the fire pump.

1, The pump body, also known as the pump casing, it is the main body of the pump. It plays the role of supporting the fixed, and is connected with the bracket for installing the bearings.

2、The role of the pump shaft is to connect with the motor by means of a coupling and transmit the motor's rotation to the impeller, so it is the main component for transmitting mechanical energy.

3、The impeller is the core part of the pump and transmits the medium through high speed rotation. The inner and outer surface on the impeller is required to be smooth to reduce the friction loss of the water flow. Of course, corrosion will occur after long-term use, and the impeller needs to be maintained, and the impeller needs to be replaced if the corrosion is serious.

4, bearing is set in the pump shaft to support the pump shaft components, there are two kinds of rolling bearings and sliding bearings. Rolling bearings use grease as lubricant; sliding bearings use transparent oil as lubricant.

5, the motor is the heart of the pump, to provide power for the impeller, is the conversion of electrical energy into mechanical energy.

6、Sealing ring is also called leakage reduction ring. In order to increase the return resistance to reduce internal leakage, delay the service life of the impeller and the pump casing, the inner edge of the pump casing and the impeller outer support combination is equipped with sealing ring, sealing gap to maintain between 0.25 ~ 1.10mm is appropriate. The gap between the impeller inlet and the pump casing will cause the water in the high-pressure area of the pump to flow to the low-pressure area through this gap, affecting the water output of the pump and reducing efficiency! Too small a gap will cause friction between the impeller and the pump casing, resulting in wear and tear.

Understand the main components of the fire pump, not only in the selection of the relevant performance, in the use of fire pumps, equipment encountered in the failure, it can be their own overhaul, simple troubleshooting problems, in the maintenance of equipment, but also effective maintenance of equipment, so as to avoid failure in the emergency, to reduce losses.

zjbetter focus on the fire pump industry for 16 years, focus on product quality and quality service, the company has a total of more than 200 fire pumps, control cabinet equipment, welcome your inquiry!

1, The pump body, also known as the pump casing, it is the main body of the pump. It plays the role of supporting the fixed, and is connected with the bracket for installing the bearings.

2、The role of the pump shaft is to connect with the motor by means of a coupling and transmit the motor's rotation to the impeller, so it is the main component for transmitting mechanical energy.

3、The impeller is the core part of the pump and transmits the medium through high speed rotation. The inner and outer surface on the impeller is required to be smooth to reduce the friction loss of the water flow. Of course, corrosion will occur after long-term use, and the impeller needs to be maintained, and the impeller needs to be replaced if the corrosion is serious.

4, bearing is set in the pump shaft to support the pump shaft components, there are two kinds of rolling bearings and sliding bearings. Rolling bearings use grease as lubricant; sliding bearings use transparent oil as lubricant.

5, the motor is the heart of the pump, to provide power for the impeller, is the conversion of electrical energy into mechanical energy.

6、Sealing ring is also called leakage reduction ring. In order to increase the return resistance to reduce internal leakage, delay the service life of the impeller and the pump casing, the inner edge of the pump casing and the impeller outer support combination is equipped with sealing ring, sealing gap to maintain between 0.25 ~ 1.10mm is appropriate. The gap between the impeller inlet and the pump casing will cause the water in the high-pressure area of the pump to flow to the low-pressure area through this gap, affecting the water output of the pump and reducing efficiency! Too small a gap will cause friction between the impeller and the pump casing, resulting in wear and tear.

Understand the main components of the fire pump, not only in the selection of the relevant performance, in the use of fire pumps, equipment encountered in the failure, it can be their own overhaul, simple troubleshooting problems, in the maintenance of equipment, but also effective maintenance of equipment, so as to avoid failure in the emergency, to reduce losses.

zjbetter focus on the fire pump industry for 16 years, focus on product quality and quality service, the company has a total of more than 200 fire pumps, control cabinet equipment, welcome your inquiry!

.png)

.png)

.png)