How to choose a reasonable pump head?

Sep 02, 2022

Share:

High head pumps can not be used at low heads

.JPG)

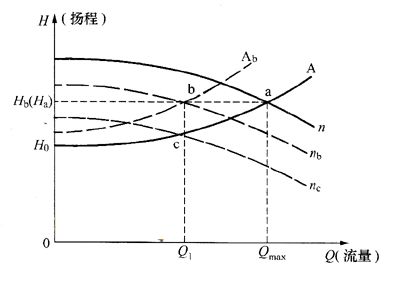

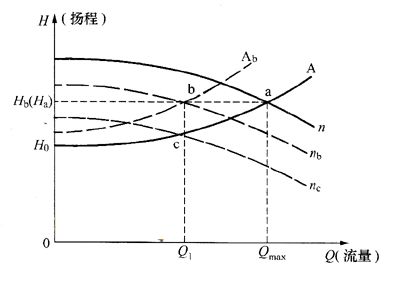

numerous ueser, before buying a pump, suppose that the lower head working conditions to choose a advanced head of the pump to use a wider range of head. In this deceiving misconception, the purchase of a water pump, choose also the pump head is veritably high. In fact, for centrifugal pumps, when the pump model is determined, its power consumption is commensurable to the factual size of the pump and inflow rate. The inflow rate will increase when the pump is used at a lower head; therefore advanced current, lower inflow rate, lower power consumption. Again, lower head, lesser inflow, lesser power consumption.

thus, in order to help motor load, it's generally needed that the factual calibrated head of the pumping head used shouldn't be lower than 60. thus, when the high head pump is used for low head, it's easy to load the motor is easy to toast up, and in serious cases the motor is burntout.However, it must be regulated with an outlet stopcock installed in the outlet pipe generally a tone- regulating stopcock( or wood block, and other styles) can be used to reduce the outlet inflow and help the motor from being overfilled, If used in an exigency. Pay attention to the temperature of the motor, if the motor is overheated, a small outlet inflow or arrestment in time can avoid burning the motor. Some druggies calculate on reducing the force voltage to force a reduction in inflow, which will increase the cargo on the motor. In fact, quite the contrary, centrifugal pumps drainage and irrigation station units outlet pipe are equipped with faucets to reduce the motor cargo for the purpose of pump arrestment should be closed before the stopcock, after the pump starts, gradationally open the stopcock so that it'll not start over current.

It should be installed in this way the low head pump is installed in front of the high head pump, i.e. the outlet water of the low head pump is transferred to the entrance of the high head pump. There's a problem that the outlet pressure of the low head pump can not exceed the upper limit of the bay pressure of the high head pump, else the miracle of overpressure leakage is likely to do.

.JPG)

numerous ueser, before buying a pump, suppose that the lower head working conditions to choose a advanced head of the pump to use a wider range of head. In this deceiving misconception, the purchase of a water pump, choose also the pump head is veritably high. In fact, for centrifugal pumps, when the pump model is determined, its power consumption is commensurable to the factual size of the pump and inflow rate. The inflow rate will increase when the pump is used at a lower head; therefore advanced current, lower inflow rate, lower power consumption. Again, lower head, lesser inflow, lesser power consumption.

thus, in order to help motor load, it's generally needed that the factual calibrated head of the pumping head used shouldn't be lower than 60. thus, when the high head pump is used for low head, it's easy to load the motor is easy to toast up, and in serious cases the motor is burntout.However, it must be regulated with an outlet stopcock installed in the outlet pipe generally a tone- regulating stopcock( or wood block, and other styles) can be used to reduce the outlet inflow and help the motor from being overfilled, If used in an exigency. Pay attention to the temperature of the motor, if the motor is overheated, a small outlet inflow or arrestment in time can avoid burning the motor. Some druggies calculate on reducing the force voltage to force a reduction in inflow, which will increase the cargo on the motor. In fact, quite the contrary, centrifugal pumps drainage and irrigation station units outlet pipe are equipped with faucets to reduce the motor cargo for the purpose of pump arrestment should be closed before the stopcock, after the pump starts, gradationally open the stopcock so that it'll not start over current.

It should be installed in this way the low head pump is installed in front of the high head pump, i.e. the outlet water of the low head pump is transferred to the entrance of the high head pump. There's a problem that the outlet pressure of the low head pump can not exceed the upper limit of the bay pressure of the high head pump, else the miracle of overpressure leakage is likely to do.